The fungi responsible for the deterioration of food products vary according to the characteristics of each product (physical-chemical characteristics, processing).

In baked goods, usually the contamination from raw materials, such as wheat flour, is eliminated in the baking step (oven). After leaving the oven, the products will go to the cooling and slicing steps and are the most critical steps for the occurrence of fungal contamination.

About 90% of the fungal contamination of breads occurs in the cooling, slicing and packaging stages, as fungal spores from the flours are dispersed in the air in the form of aerosols. These aerosols are a source of contamination and are deposited on the surface of freshly baked bread during the cooling stage, causing the product to be recontaminated.

Air quality monitoring is important so that preventive or corrective measures are taken, according to air analyses, detecting and quantifying microorganisms present in the air and which can generate low, intermediate and high risk limits for food contamination.

In order to improve the air quality and restrict the access of spores to baked products, it is necessary to improve the hygiene of the manufacturing area: avoiding the accumulation of product residue in machines, trays, slicers; keeping floors, walls, ceilings clean, as well as any surface that comes into contact with the product; keeping the flour handling areas separate from the cooling and packaging areas. The effectiveness of Good Manufacturing Practices must also be verified as per the standards described by ANVISA and their importance to employees must be emphasized.

How is air collection done?

There are several methodologies for analyzing ambient air, the most common being:

– Plate analysis by natural air sedimentation;

– Air suction with appropriate equipment with attached plate;

In both methodologies, a Petri dish with the specific culture medium for fungi is used and the air collection is carried out at strategic points of the manufacturing plant where there is probably greater contamination of the final product.

Pman air collection

Pman uses the air suction methodology. Inside the equipment, a petri dish is inserted with the culture medium that contains specific nutrients for the growth of fungi.

For each analyzed point, a new and identified plate is used and sent to the microbiology laboratory.

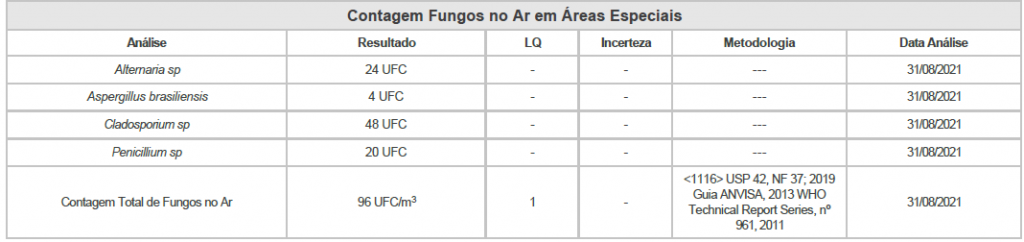

The results are expressed in CFU/m³ (colony forming units per cubic meter), the table below shows the result of a collection containing the most common fungi in the bakery industry.

We used the Fung Scale (Daniel Y. C. Fung) below to interpret the results and assess the air quality.

According to the risks, Pman makes recommendations for corrective or preventive actions, in order to reduce the contamination and consequently the SAC complaints due to mold.

Pman has the team that will help you by taking all measures against contamination.