What is microencapsulation?

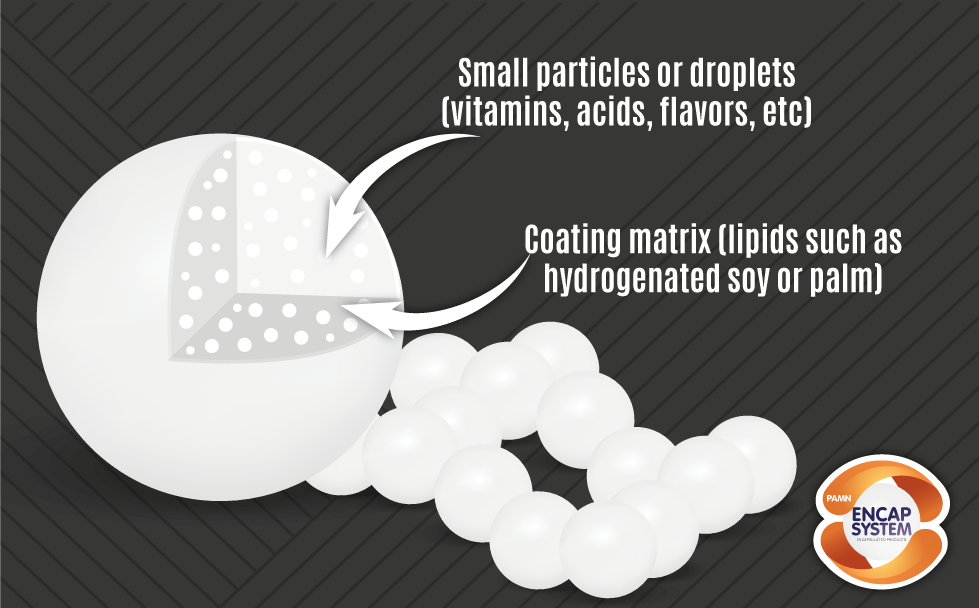

Microencapslation technology is based on applying a coating around small particles of a substance of interest. The substance might be a vitamin you wish to protect, and acid or base you want to release at a specific point in the process, delicate flavors and so on.